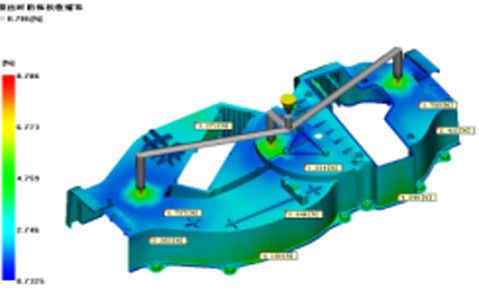

The way the plastic flows into the mould is of paramount importance in determining the quality of the part. The process of filling the mould can be distinctly analyzed with the ability to predict pressure, temperature, and stress.

Consider the effect of the key molding settings of mold temperature, melt temperature, and fill time on part quality,also Packing Pressure and Time. Moldflow can be used to evaluate such as optimum processing conditions,Size of molding window,Material selection,Pressure required to fill a part, Gate locations,Wall thickness。

Moldflow is an effective tool for comparing the implications of various gate designs, including:Gate location,Molding window size at the gate location, Filling pattern, Gate size based on shear rate.

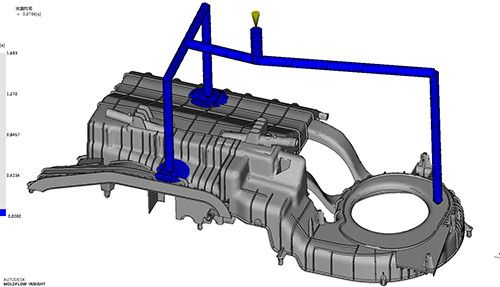

· Runner System DesignOnce the hot runner system is added to the model, the size of the hot drops needs to be adjusted to ensure the filling pattern in the part is still acceptable.

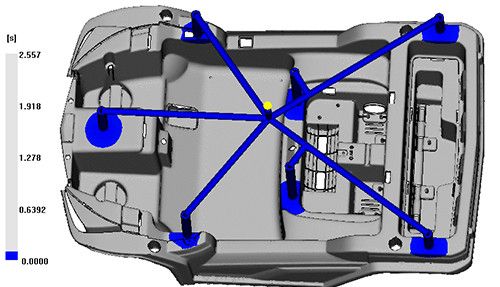

· Cooling System DesignA mold cooling system typically consists of the following items:Temperature controlling unit,Pump,Supply manifold,Hoses,Cooling channels in the mold, Collection manifold.

JMT offer a complete design solution, providing customer support at all of a product development cycle. If you have a new idea , JMT will develop your ideas, exploring innovative solutions from concept sketches, all the way through to a fully engineered and marketable solution.

Our technical team can draw upon many years’ experience from the multiple disciplines that are required to develop a successful molded product. We analyses the component design of all new projects and apply our experience of ‘design for manufacture‘ to maximize mold ability, minimize second operations, reduce assembly time and simplify tooling – adding value at every stage, resulting in the ideal combination of material, mold, manpower, and machine for efficient and cost-effective production

We take pride in having worked in many partnerships on difficult projects, introducing innovative solutions ensuring a successful and timely product launch. We cannot stress enough the importance of having your manufacturing partner involved early during the early stage of the product design process – ultimately saving time, cost and a whole load of hassle!

As part of our design for manufacture service we can recommend suitable thermoplastic, customers and options for additives specific to the qualities your product requires.

Our polymer experience ranges from the commodity to exotic materials, talk to us if you need guidance on material selection.

You, as the customer, know what you want and we provide a personal design service to make sure you get it. We take your design and apply years of industry knowledge to ensure that you end up with the product you want, manufactured efficiently by JMT .

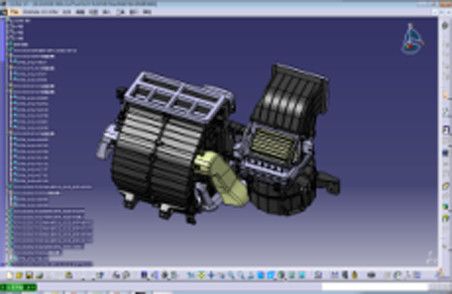

Primary CAD system: Uni-graphics/ NX8/10

. Single Seats of Catia / Pro E / Solid-works

. Auto-desk Mold-flow / MPI

. Mold Feasibility Software

. CAM:UG/HYPERMILLUG / Hyper mill

. Type of document :IGS ,STP ,X-T